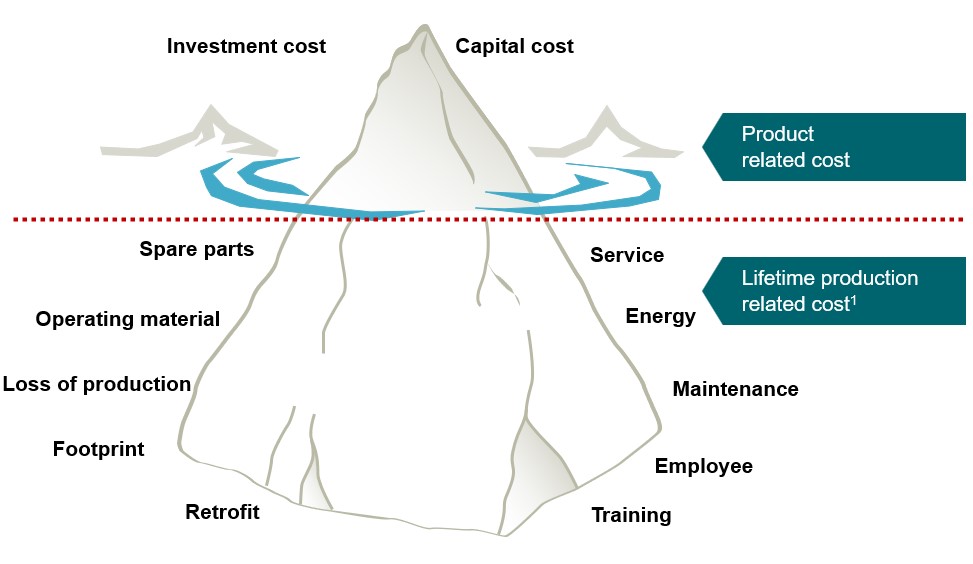

Total Cost of Ownership

Reduce by consistent standardization

How I can help you !

I know that standardization and the use of TCO (Total Cost of Ownership) boundary conditions are not short-term measures to save investment costs. It requires a long-term perspective and the willingness to pursue this path consistently.

I am convinced that gradual standardization is possible and that you will see the clear benefits at every step.

With my advice and my well-founded expertise, I am happy to provide you with targeted support on this path :

• Analysis of your current situation: Together we analyze your current processes and identify potential for optimization.

• Development of an individual strategy: Based on your specific requirements, I develop a tailor-made strategy for standardization and use of the TCO boundary conditions.

• Support during implementation: I will assist you in implementing the strategy and support you in overcoming challenges.

• Continuous optimization: Even after implementation, I am available for questions and further optimizations.

I can help you to make your investments more efficient and reduce costs in the long term. Let's go down this path together.

for endcustomer (Automotive, 1st Tier)

machine and linebuilder

- At the moment, machine/line builders are repeatedly faced with the challenge of having to design the equipment for an end customer order in accordance with the end customer's specifications or only being able to install the cheapest components in the plant for commercial reasons. In some cases, he can also place his own standard with the customer. The TCO concept often plays no role at the moment.

In the future, due to technical trends such as the creation of a digital twin, standard interfaces to the cloud and the use of AI and/or IIoT services, standardization will once again play a greater role.

I can support you with :

- Analysis of customer-specific specifications and tips for reaching consensus with your end customers.

- Information on future trends in component production (powertrain) at automotive manufacturers and their suppliers. Production and assembly lines required in the future. Cooperation with partners (funding projects, universities).

- Advice on the sensible standardization of the automation solution for your products (machines / systems).

supplier of Automationcomponents and solutions without defined standard concepts for their customers

- An essential key to the successful placement of an automation solution with an end customer or machine-/line-builder is the existence of a “standardized” automation solution. Ideally, this should be developed together with the end customer and the corresponding machine-/line-builder!

The best way to do this is through an organized consortium consisting of end customers, machine-/line-builder and universities. A standardized automation concept always consists of several building blocks. This enables your customers to use standardization in stages. Here I can offer my expertise for :

- Information and procedure to create a standard for your automation portfolio and solutions together with machine-/line-builder and end customers.

- Definition of standardization modules in order to be able to offer your customers a step-by-step concept for standardization.

- An appropriate sales and support concept is necessary to place a standardized automation solution on the market. I can support your company with my experience :

- in the definition of an appropriate sales organization.

- for information about a support organization and support tools.

about me :

Klaus Kasperek

- Since over 20 years I have been successfully dealing with topics related to standardization of automation concepts for production plants for automotive powertrain as well as 1st and 2nd tier automotive component plants.

- In recent years, I have worked as an international account manager for Siemens AG for various international automobile manufacturers in the powertrain sector.

- Until the beginning of 2024, I was responsible at Siemens AG for the technical standard in the automotive powertrain area (Transline) and for standardized automation concepts in the area of ePowertrain (electric motor, battery and fuel cell).

- As project manager for Siemens AG, I was successfully responsible for a public funding project in the Fuel-Cell topic.

- Close cooperation with various universities (RWTH-PEM, KIT,...).

- You can find much more information about me at "LinkedIn"

actual

Our customers, our industry expertise

- Automotive Powertrain, 1st and 2nd Tier Automotive Planning and maintenance teams

- Machines and production systems manufacturer for automotive powertrain and 1st and 2nd tier automotive component plants

- Supplier of automation equipment and solutions for automotive powertrain

Of course, standardization can be applied in many areas of industry. Of course I also offer my expertise here!

contact

Autconsta • Consulting

Mobil: +49 172

8490416

E-Mail: klaus.kasperek@autconsta.com